ANSYS Workbench

Thermal, Fluid, and Structural Load Simulations on ANSYS Fluent and Static Structure

Conjugate Heat Transfer - Electronics Cooling

-

At T_in = 60°C and 0.01 ≤ Vin ≤ 0.08m/s,

Tout ∝ Vin represents the effect of conductive heat transfer between the fluid and the solid -

Difference in T_out is ~ 25°C considering the effect of buoyancy

-

The heat sink accounts for ~33% of the total heat transfer with Boussinesq’s method as compared to ~25% in the case of constant density

-

FC3283 shows better heat dissipation as compared to Mineral-Oil. Due to β_FC>β_MO and Cp_FC<Cp_MO

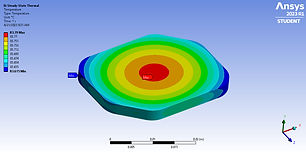

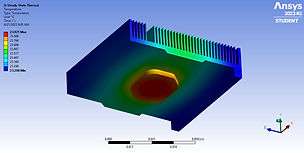

Thermal Analysis of Heat Sink on Intel Atom

-

3D steady-state thermal analysis of heat sink on Intel Atom dual-core chip to demonstrate the cooling effect of the heat sink in electronics

-

Copper heat sink on Aluminum chip, with ambient air at 22°C

-

Power dissipated by the chip is 6.5 W and the operating temperature is -35°C ~ 80°C

-

Maximum temperature without heat sink: 84°C

-

Maximum temperature with heat sink: 24°C

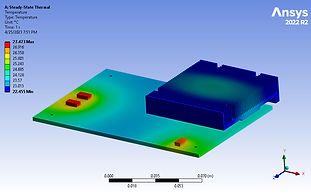

PCB Thermal Analysis

-

3D steady-state thermal analysis of PCB

-

Copper heat sink on Aluminum chip and 3 1W high power components on FR-4 Board with ambient air at 22°C and 55 W/m*K

Three Phase Transient Flow

-

Three phase transient simulation representing water droplet falling into liquid diesel in an air filled domain

-

Total time: 0.7 s | Time step: 0.001 s

-

Volume of Fluid method | Laminar Flow

-

Domain size: 25cm x 25cm

Two Phase Transient Flow 3D

-

Glycerine droplet flowing over a 30 degree inclined plane under influence of gravity

-

Total time: 0.2 s | Time step: 0.0005 s

-

V.O.F. method | Laminar Flow

-

Domain size: 0.18m x 0.08m x 0.04m

-

Droplet radius: 0.02m

Two Phase Transient Flow 2D

-

Methane leakage from a pressurized chamber

-

Total time: 6 s | Time step: 0.01 s

-

V.O.F. method | K-Omega model

-

Domain size: 60m x 35m

-

Boundary conditions: Pressure Inlet = 50 Pa and

surrounding Pressure Outlet = 0 Pa -

Additional case:

Wind Velocity is given by u = 0.6 y – 0.02 y^2

Compressible Transient Flow

-

3D Model of interconnected pressure cylinder

-

Initial Condition: Small cylinder = 10200 Pa

-

Large cylinder = 10000 Pa and Temperature = 300 K

-

Fluid: Air (ideal gas)

-

k-omega turbulence model | density based solver study the density, temperature, and velocity for

t = 0 - 0.05 secs -

CAD Model created using Solidworks.

-

Domain size: 0.7 m x 0.2 m and diameter = 0.2 m

-

Total time: 0.05 s | Time step: 0.0005 s

Thermo-Fluid: Viscous Heating

-

3D thermo-fluid analysis of Engine oil flowing through a coil at 1 m/s, 2 m/s, and 4 m/s

-

Laminar Model | Velocity inlet | Pressure outlet

-

3D CAD Helical pipe model created using Solidworks

-

Helix: X(τ) = R cos(τ) | Y(τ) = R sin(τ) | Z(τ) = C τ

-

Pipe diameter = 0.08 m, Helix radius = 0.3 m

-

Another simulation with Liq. Water and uniform heat flux of 700 W/m^2 on wall was analyzed.

-

This was done to study the effect of flow velocity on fluid temperature with inlet velocities 0.008 m/s, 0.016 m/s, 0.032 m/s, and 0.064 m/s.

-

Observed linear proportionality between flow velocity and temperature due to viscous heating